A01 - Joinability prognosis

The application of mechanical joining technology offers the possibility of joining mixed structures with a wide range of specifications and material-geometry combinations. Due to the limited transparency of the processes externally, the high number of combinable tool variants as well as variable force- and stroke-based process parameters, a comprehensive validation of the joinability in versatile process chains along the process steps is not possible with a conventional, experiment-based approach.

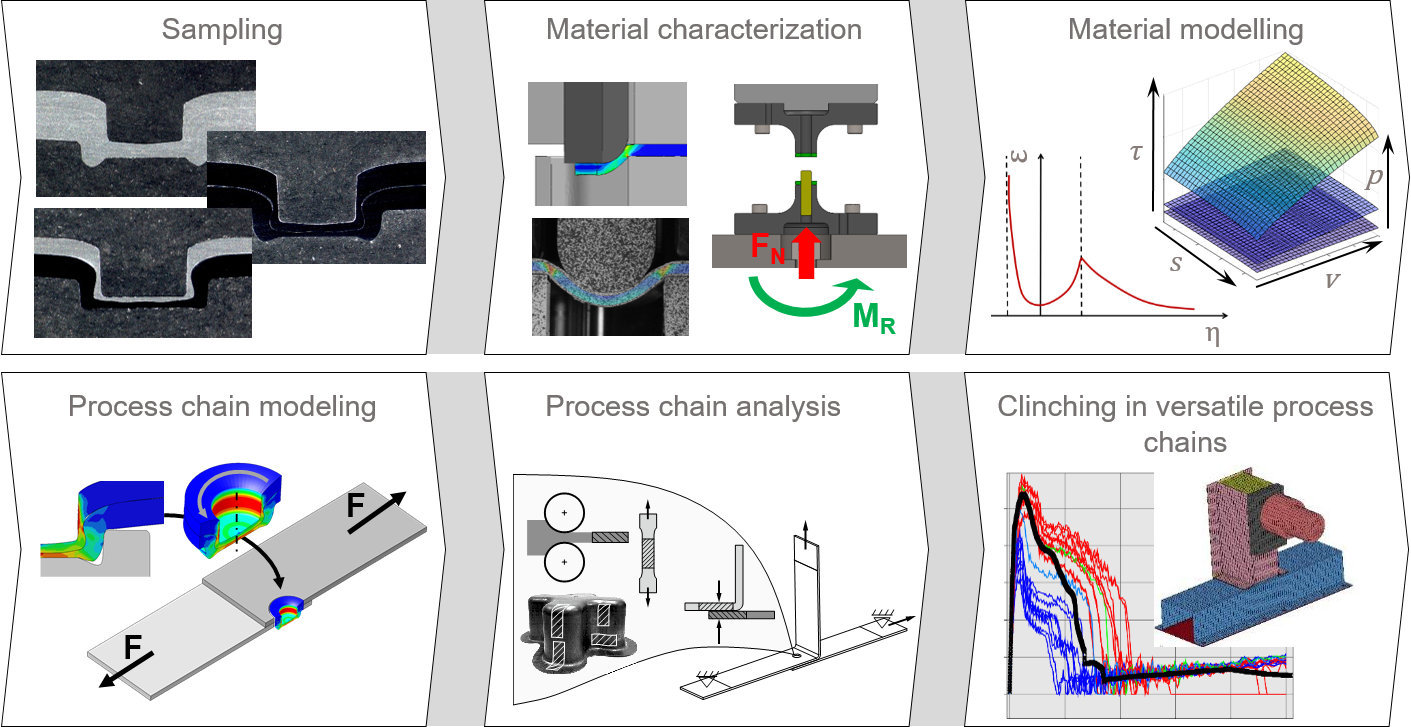

The vision of the subproject is therefore the development of methods for the holistic prediction of the joining safety, joining suitability and joining possibility along the versatile process chain. For the necessary comprehensiveness with regard to the joining part materials, joining processes and operating conditions, in addition to the development of methods, already developed methods of other subprojects of the TRR are integrated in TP A01. Combined methods from experimental test methods and simulation models, which describe the joint behavior on the basis of the material behavior, will be developed in order to open up fundamental operating principles and to enable comprehensive prediction on the basis of simulation. Finally, the methods will be used to develop targeted flexibilization and robustification measures for versatile process chains against the varying input variables.

In TP A01, a simulation strategy is being developed that virtually maps the process steps of joining part production, joining process and loading phase and allows the relevant state variables, such as geometry, material hardening and damage, to be transferred for a continuous simulation of mechanical joinability. The simulation model is to be used in an iterative process to investigate the usefulness and sensitivity of the transferred state variables with regard to the overall process and to the respective subsequent process steps. For the validation of the simulation models, the entire process chain will be reproduced experimentally in detail, with geometry and material condition being determined as locally as possible after each process step, as well as the process variables. This requires the development of new test methods for characterizing the frictional properties and damage behavior of joining part materials under the complex boundary conditions of the process chain. In addition, suitable specimen forms must be developed which can run through the entire process chain and allow targeted adjustment of the material condition during joining part production in the area of the joining zone as well as combined loading conditions.

Fügbarkeitsprognose (1/2)

Fügbarkeitsprognose (2/2)

Publications

Numerical analysis of the robustness of clinching process considering the pre-forming of the parts

C.R. Bielak, M. Böhnke, R. Beck, M. Bobbert, G. Meschut, Journal of Advanced Joining Processes. (2020).

Development of a numerical method for analyzing the robustness of clinching in versatile process chains

C.R. Bielak, M. Böhnke, M. Bobbert, G. Meschut, in: Material Science and Engineering Congress - MSE 2020, n.d.

Further development of a numerical method for analyzing the load capacity of clinched joints in versatile process chains

C.R. Bielak, M. Böhnke, M. Bobbert, G. Meschut, in: ESAFORM 2021, n.d.

Concept development of a method for identifying friction coefficients for the numerical simulation of clinching processes

M. Böhnke, M.S. Rossel, C.R. Bielak, M. Bobbert, G. Meschut, The International Journal of Advanced Manufacturing Technology (2021).

Development of a Method for the Identification of Friction Coefficients in Sheet Metal Materials for the Numerical Simulation of Clinching Processes

M.S. Rossel, M. Böhnke, C.R. Bielak, M. Bobbert, G. Meschut, Key Engineering Materials 883 (2021) 81–88.

Influence of rivet length on joint formation on self-piercing riveting process considering further process parameters

F. Kappe, C.R. Bielak, V. Sartisson, M. Bobbert, G. Meschut, in: ESAFORM 2021, University of Liege, 2021.

Influence of various procedures for the determination of flow curves on the predictive accuracy of numerical simulations for mechanical joining processes

M. Böhnke, F. Kappe, M. Bobbert, G. Meschut, Materials Testing 63 (2021) 493–500.

Numerical and experimental identification of fatigue crack initiation sites in clinched joints

L. Ewenz, C.R. Bielak, M. Otroshi, M. Bobbert, G. Meschut, M. Zimmermann, Production Engineering 16 (2022) 305–313.

Influence of heat treatment on the suitability for clinching of the aluminium casting alloy AlSi9

M. Neuser, M. Böhnke, O. Grydin, M. Bobbert, M. Schaper, G. Meschut, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (2022).

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.R. Bielak, J. Troschitz, Journal of Advanced Joining Processes 5 (2022).

Functionality Study of an Optical Measurement Concept for Local Force Signal Determination in High Strain Rate Tensile Tests

M. Böhnke, E. Unruh, S. Sell, M. Bobbert, D. Hein, G. Meschut, Key Engineering Materials 926 (2022) 1564–1572.

Development of a Modified Punch Test for Investigating the Failure Behavior in Sheet Metal Materials

M. Böhnke, C.R. Bielak, M. Bobbert, G. Meschut, in: The Minerals, Metals & Materials Series, Springer International Publishing, Cham, 2022.

Experimental and numerical investigation of the influence of multiaxial loading conditions on the failure behavior of clinched joints

M. Böhnke, C.R. Bielak, M. Bobbert, G. Meschut, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (2022).

Review on mechanical joining by plastic deformation

G. Meschut, M. Merklein, A. Brosius, D. Drummer, L. Fratini, U. Füssel, M. Gude, W. Homberg, P.A.F. Martins, M. Bobbert, M. Lechner, R. Kupfer, B. Gröger, D. Han, J. Kalich, F. Kappe, T. Kleffel, D. Köhler, C.-M. Kuball, J. Popp, D. Römisch, J. Troschitz, C. Wischer, S. Wituschek, M. Wolf, Journal of Advanced Joining Processes 5 (2022).

Provision of cross-domain knowledge in mechanical joining using ontologies

C. Zirngibl, P. Kügler, J. Popp, C.R. Bielak, M. Bobbert, D. Drummer, G. Meschut, S. Wartzack, B. Schleich, Production Engineering (2022).

Development of a Numerical 3D Model for Analyzing Clinched Joints in Versatile Process Chains

C.R. Bielak, M. Böhnke, M. Bobbert, G. Meschut, in: The Minerals, Metals & Materials Series, Springer International Publishing, Cham, 2022.

Numerical investigation of a friction test to determine the friction coefficients for the clinching process

C.R. Bielak, M. Böhnke, M. Bobbert, G. Meschut, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (2022).

Numerical and experimental identification of fatigue crack initiation sites in clinched joints

L. Ewenz, C.R. Bielak, M. Otroshi, M. Bobbert, G. Meschut, M. Zimmermann, Production Engineering 16 (2022) 305–313.

A Review on the Modeling of the Clinching Process Chain - Part I: Design Phase

B. Schramm, S. Martin, C. Steinfelder, C.R. Bielak, A. Brosius, G. Meschut, T. Tröster, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes 6 (2022).

A Review on the Modeling of the Clinching Process Chain - Part II: Joining Process

B. Schramm, J. Friedlein, B. Gröger, C.R. Bielak, M. Bobbert, M. Gude, G. Meschut, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes (2022).

Numerical investigation of the clinched joint loadings considering the initial pre-strain in the joining area

S. Martin, C.R. Bielak, M. Bobbert, T. Tröster, G. Meschut, Production Engineering (2022).

Numerical analysis of failure modeling in clinching process chain simulation

C.R. Bielak, M. Böhnke, J. Friedlein, M. Bobbert, J. Mergheim, P. Steinmann, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

A calibration method for failure modeling in clinching process simulations

M. Böhnke, C.R. Bielak, J. Friedlein, M. Bobbert, J. Mergheim, P. Steinmann, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Experimental and Numerical Investigation of Clinched Joints Under Shear Tensile Loading at High Strain Rates

M. Böhnke, C.R. Bielak, M. Bobbert, G. Meschut, in: Lecture Notes in Mechanical Engineering, Springer Nature Switzerland, Cham, 2023.

Influence of plastic orthotropy on clinching of sheet metal

J. Friedlein, C.R. Bielak, M. Böhnke, M. Bobbert, J. Mergheim, P. Steinmann, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Development of a friction model for the numerical simulation of clinching processes

M. Böhnke, C.R. Bielak, R. Beck, M. Bobbert, G. Meschut, Friction (2024).

Material Parameter Identification for a Stress-State-Dependent Ductile Damage and Failure Model Applied to Clinch Joining

J. Friedlein, M. Böhnke, M.C. Schlichter, M. Bobbert, G. Meschut, J. Mergheim, P. Steinmann, Journal of Manufacturing and Materials Processing 8 (2024).

Mechanical joinability of microstructurally graded structural components manufactured from hypoeutectic aluminium casting alloys

M. Neuser, M.C. Schlichter, K.-P. Hoyer, M. Bobbert, G. Meschut, M. Schaper, 44th Conference of the International Deep Drawing Research Group (IDDRG 2025) 408 (2025).

Experimental and numerical investigation of the influence of rolling-induced sheet metal deformation on SPR joints

M.C. Schlichter, Ö. Harabati, J.-P. Ludwig, M. Böhnke, C.R. Bielak, M. Bobbert, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, Paestum, 2025.

High-cycle fatigue testing and parameter identification for numerical simulation of aluminum alloy EN AW-6014

C. Chen, M.C. Schlichter, S. Harzheim, M. Hofmann, M. Bobbert, G. Meschut, T. Wallmersperger, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Cross-process damage modeling: A process-chain case study of clinching and self-pierced riveting for aluminum connections

Ö. Harabati, C.R. Bielak, M. Böhnke, M.C. Schlichter, M. Brockmeier, M. Bobbert, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Application of stress-state-dependent ductile damage and failure model to clinch joining for a wide range of tool and material combinations

J. Friedlein, S. Lüder, J. Kalich, H.C. Schmale, M. Böhnke, M.C. Schlichter, M. Bobbert, G. Meschut, P. Steinmann, J. Mergheim, Journal of Advanced Joining Processes 11 (2025).

Simulation of the joining process of graded hardened multi-range capable rivets

P.K. Holtkamp, C.R. Bielak, M. Bobbert, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Show all publications