C04 - Local and Integrated In-situ Analysis of Process- und Load-Caused Damage Effects in Joints

The deformation and damage phenomena that occur during the manufacture and loading of mechanical joints cannot yet be directly observed and characterised in detail due to the limited accessibility of the joint. Instead, a joint must first be unloaded and elaborately prepared and analysed, generally destructively. During this ex-situ analysis, elastic deformations reset as a result of the unloading, whereby cracks that have been introduced can potentially close. Thus these cracks cannot be detected or can only be detected to a limited extent.

The overall objective of this sub-project is the development and implementation of two complementary experimental methods for the non-destructive in-situ analysis of joints. The two methods to be developed complement each other in such a way that they enable a spatially and temporally highly resolved analysis of the joint both during its formation and under load. For the development and adaptation of the two measurement procedures as well as the phenomenological allocation of the test data, a method-based procedure for the interpretation of the temporally and spatially resolved measurement information is to be developed. The sub-project makes a significant contribution to achieving the goal of versatility in mechanical joining technology, as both the joint production and the joint load can be subjected to a detailed analysis that has not been possible so far and thus the cause-effect relationships of both life phases can be investigated.

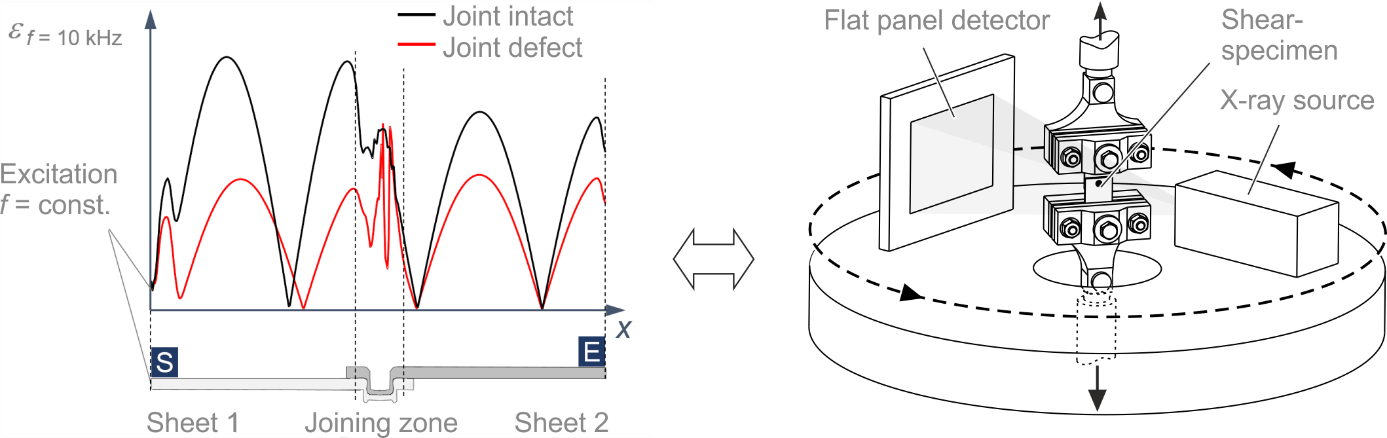

A novel in-situ procedure using X-ray computed tomography (in-situ CT) is to be developed for local high-resolution analysis, with which the joining zone can be recorded three-dimensionally during the joining process or stress. CT as a tool for evaluating the quality of joints in larger assemblies can only be used to a limited extent due to the limited measuring volume. This is where the second method to be developed, the transient dynamic analysis (TDA), comes in. It is based on the introduction of ultrasonic waves into the joint and on the recording of the response depending on the energy contributions transmitted through the joint. The dissipated energy contributions as a result of material damage or an inadequate joint can be distinguished on the basis of their characteristics via frequency and amplitude. By introducing the ultrasonic waves, changes in the response behaviour and thus a change in the characteristic profile can be detected with high temporal resolution. Thus, the detailed CT images enable a clear assignment of the measured characteristic TDA response profiles to particular damage characteristics in the material.

In situ Analyse

Publications

Investigation of Clinched Joints – A Finite Element Simulation of a Non-destructive Approach

B. Sadeghian, C. Guilleaume, R. Lafarge, A. Brosius, Lecture Notes in Production Engineering (2020) 116–124.

Experimental and Numerical Studies on the Deformation of a Flexible Wire in an Injection Moulding Process

D. Köhler, B. Gröger, R. Kupfer, A. Hornig, M. Gude, Procedia Manufacturing 47 (2020) 940–947.

Clinching in in-situ CT—A numerical study on suitable tool materials

D. Köhler, R. Kupfer, M. Gude, Journal of Advanced Joining Processes 2 (2020) 100034.

Clinching in in-situ CT—A numerical study on suitable tool materials

D. Köhler, R. Kupfer, M. Gude, Journal of Advanced Joining Processes 2 (2020).

Clinching in In-situ CT – Experimental Study on Suitable Tool Materials

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, ESAFORM 2021 (2021).

In Situ Computed Tomography—Analysis of a Single-Lap Shear Test with Clinch Points

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, Materials 14 (2021) 1859.

Computed tomography investigation of the material structure in clinch joints in aluminium fibre-reinforced thermoplastic sheets

B. Gröger, D. Köhler, J. Vorderbrüggen, J. Troschitz, R. Kupfer, G. Meschut, M. Gude, Production Engineering (2021).

A New Non-destructive Testing Method Applied to Clinching

R. Lafarge, A. Wolf, C. Guilleaume, A. Brosius, Minerals, Metals and Materials Series (2021) 1461.

A Method for Characterization of Geometric Deviations in Clinch Points with Computed Tomography and Transient Dynamic Analysis

D. Köhler, B. Sadeghian, R. Kupfer, J. Troschitz, M. Gude, A. Brosius, Key Engineering Materials 883 (2021) 89–96.

A Method for Characterization of Geometric Deviations in Clinch Points with Computed Tomography and Transient Dynamic Analysis

D. Köhler, B. Sadeghian, R. Kupfer, J. Troschitz, M. Gude, A. Brosius, Key Engineering Materials 883 (2021) 89–96.

Computed tomography investigation of the material structure in clinch joints in aluminium fibre-reinforced thermoplastic sheets

B. Gröger, D. Köhler, J. Vorderbrüggen, J. Troschitz, R. Kupfer, G. Meschut, M. Gude, Production Engineering 16 (2021) 203–212.

In Situ Computed Tomography—Analysis of a Single-Lap Shear Test with Clinch Points

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, Materials 14 (2021).

Clinching in In-situ CT – Experimental Study on Suitable Tool Materials

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, ESAFORM 2021 (2021).

Characterisation of lateral offsets in clinch points with computed tomography and transient dynamic analysis

D. Köhler, B. Sadeghian, J. Troschitz, R. Kupfer, M. Gude, A. Brosius, Journal of Advanced Joining Processes 5 (2021).

Clinching in In Situ CT—A Novel Validation Method for Mechanical Joining Processes

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, in: The Minerals, Metals & Materials Series, Springer International Publishing, Cham, 2022.

Joining Processes for Fibre-Reinforced Thermoplastics: Phenomena and Characterisation

J. Troschitz, B. Gröger, V. Würfel, R. Kupfer, M. Gude, Materials 15 (2022).

Characterisation of lateral offsets in clinch points with computed tomography and transient dynamic analysis

D. Köhler, B. Sadeghian, J. Troschitz, R. Kupfer, M. Gude, A. Brosius, Journal of Advanced Joining Processes 5 (2022) 100089.

Investigations on Combined in situ CT and Acoustic Analysis during Clinching

D. Köhler, R. Stephan, R. Kupfer, J. Troschitz, A. Brosius, M. Gude, in: Key Engineering Materials, Trans Tech Publications, Ltd., 2022, pp. 1489–1497.

Experimental Measurement Method and Evaluation of an Analytical Approach for Sound Conduction through Multiple Clinched Sheets

R. Stephan, A. Brosius, in: The 28th Saxon Conference on Forming Technology SFU and the 7th International Conference on Accuracy in Forming Technology ICAFT, MDPI, 2022.

Approach to Determine the Characteristic Dimensions of Clinched Joints by Industrial X-ray Computed Tomography

M. Busch, D. Köhler, T. Hausotte, R. Kupfer, J. Troschitz, M. Gude, in: 2022.

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.R. Bielak, J. Troschitz, Journal of Advanced Joining Processes 5 (2022).

Review on mechanical joining by plastic deformation

G. Meschut, M. Merklein, A. Brosius, D. Drummer, L. Fratini, U. Füssel, M. Gude, W. Homberg, P.A.F. Martins, M. Bobbert, M. Lechner, R. Kupfer, B. Gröger, D. Han, J. Kalich, F. Kappe, T. Kleffel, D. Köhler, C.-M. Kuball, J. Popp, D. Römisch, J. Troschitz, C. Wischer, S. Wituschek, M. Wolf, Journal of Advanced Joining Processes 5 (2022).

Approach to Determine the Characteristic Dimensions of Clinched Joints by Industrial X-ray Computed Tomography

M. Busch, D. Köhler, T. Hausotte, R. Kupfer, J. Troschitz, M. Gude, E-Journal of Nondestructive Testing 27 (2022).

Untersuchung zum Einfluss radioopaker Zwischenschichten bei der in-situ CT geclinchter Verbindungen

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, in: M. Zimmermann (Ed.), Tagungsband zur Werkstoffprüfung 2022, Dresden, 2022.

Clinching in In Situ CT—A Novel Validation Method for Mechanical Joining Processes

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, in: The Minerals, Metals & Materials Series, Springer International Publishing, Cham, 2022.

Investigations on Combined <i>In Situ</i> CT and Acoustic Analysis during Clinching

D. Köhler, R. Stephan, R. Kupfer, J. Troschitz, A. Brosius, M. Gude, Key Engineering Materials 926 (2022) 1489–1497.

Anrisserkennung an geclinchten Proben während einer zyklischen Belastung unter Nutzung eines Scanning Laser Doppler Vibrometers

A. Brosius, L. Ewenz, R. Stephan, M. Zimmermann, in: M. Zimmermann (Ed.), Tagung Werkstoffprüfung 2022, Deutsche Gesellschaft für Materialkunde e.V. (DGM), 2023.

Investigations on Continuous Transient Dynamic Analysis of Clinched Aluminum Sheets

G. Reschke, A. Brosius, in: Lecture Notes in Production Engineering, Springer Nature Switzerland, Cham, 2023.

Comparison of ex- and in-situ investigations of clinched single-lap shear specimens

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

In-situ Computed Tomography and Transient Dynamic Analysis of a Single-Lap Shear Test with a Composite-Metal Clinch Point

D. Köhler, R. Stephan, R. Kupfer, J. Troschitz, A. Brosius, M. Gude, in: Lecture Notes in Production Engineering, Springer International Publishing, Cham, 2023.

In-situ computed tomography and transient dynamic analysis – failure analysis of a single-lap tensile-shear test with clinch points

G. Reschke, D. Köhler, R. Kupfer, J. Troschitz, M. Gude, A. Brosius, Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering (2024).

In-situ computed tomography and transient dynamic analysis – failure analysis of a single-lap tensile-shear test with clinch points

G. Reschke, D. Köhler, R. Kupfer, J. Troschitz, M. Gude, A. Brosius, Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering (2024).

In-situ computed tomography analysis of the failure mechanisms of thermomechanically manufactured joints with auxiliary joining element

T. Borgert, D. Köhler, E. Wiens, R. Kupfer, J. Troschitz, W. Homberg, M. Gude, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications 238 (2024) 2299–2306.

In-situ CT of the clinching process – Influence of settling effects due to process interruptions

D. Köhler, R. Kupfer, J. Troschitz, M. Gude, in: Materials Research Proceedings, Materials Research Forum LLC, 2024.

Transient dynamic analysis: Performance evaluation of tactile measurement

G. Reschke, A. Brosius, in: Materials Research Proceedings, Materials Research Forum LLC, 2025, pp. 293–300.

In situ computed tomography – Analysis of settling effects during single-lap shear tests with clinch points

D. Köhler, J. Troschitz, R. Kupfer, M. Gude, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Show all publications