C01 – Mechanical joining without auxiliary elements

Behind the background of an increasing demand for a resource-efficient production, lightweight constructions are a recent trend. Here, it is aimed to utilize the best material at the right place. Semi-finished products from continuous fibre-reinforced thermoplastics (CFRTs) offer superb weight-related mechanical properties and are gaining in importance alongside metallic lightweight materials. However, these materials have limitations, especially under high temperatures or abrasive wear. For this reason, multi-material systems are increasingly used to combine the specific strengths of the respective materials. However, due to the different physical and chemical properties, the joining technology represents a central challenge, causing established joining techniques to often reach their limits and a need for new technologies to emerge. An efficient approach to this is the joining without auxiliary parts by means of metallic pins, which can be produced by forming.

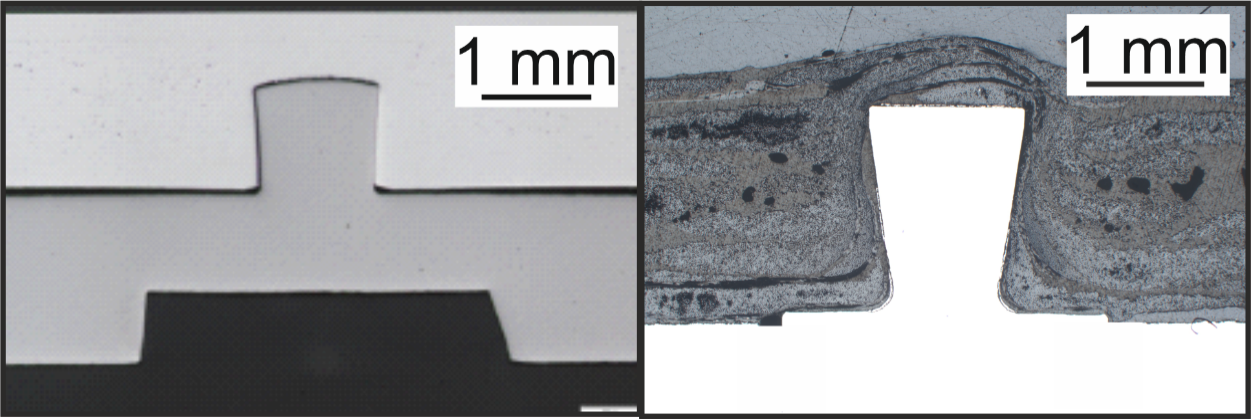

A pin is defined as a protrusion on one joining partner that ca be inserted in the second joining partner. Thereby, both a direct pin pressing as well as a combination of hole forming and pin insertion with subsequent caulking step are possible. The aim of the subproject is the fundamental investigation of described approach. Therefore, in the first phase the fundamentals of the pin manufacturing and joining process need to be examined.

It is possible to react to changing requirements on the joint through variation of the pin structure at the pin manufacturing step and to consequently allow the application in versatile process chains. Besides the pin manufacturing, the research of suitable joining processes is main goal. Thereby, in CFRT/Metal joining, different process routes with different heating strategies are to be in investigated: Via variable process strategies it becomes possible to react to different conditions (e.g. composition of the CFRT component). The gained knowledge of the pin manufacturing as well as the joining process and associated simulations will be fed back into the development of optimized pin geometries.

The exchange with other subprojects is essential for the validation of their developed damage models and dimension strategies. The final assessment of the pin geometries will be conducted based on the investigations of the joint properties.

Hilfsfügeteilfreies Fügen

Publications

Mechanical joining without auxiliary element by cold formed pins for multi-material-systems

M. Kraus, P. Frey, T. Kleffel, D. Drummer, M. Merklein, AIP Conference Proceedings 2113 (2019) 050006.

Potential of Joining Dissimilar Materials by Cold Formed Pin-Structures

M. Kraus, M. Merklein, Journal of Materials Processing Technology 283 (2020) 116697.

Energy direction in ultrasonic impregnation of continuous fiber-reinforced thermoplastics

J. Popp, M. Wolf, T. Mattner, D. Drummer, Journal of Composites Science 5 (2021) 239.

Data-driven analysis of cold-formed pin structure characteristics in the context of versatile joining processes

D. Römisch, C. Zirngibl, B. Schleich, S. Wartzack, M. Merklein, IOP Conference Series: Materials Science and Engineering 1157 (2021) 012077.

Fiber Orientation Mechanism of Continuous Fiber Reinforced Thermoplastics Hybrid Parts Joined with Metallic Pins

J. Popp, T. Kleffel, D. Römisch, T. Papke, M. Merklein, D. Drummer, Applied Composite Materials 28 (2021) 951–972.

Joining of CFRT-steel hybrid parts via hole-forming and subsequent pin caulking

D. Römisch, J. Popp, D. Drummer, M. Merklein, Production Engineering (2021).

Experimental study on joining by forming of hct590x + z and en-aw 6014 sheets using cold extruded pin structures

D. Römisch, M. Kraus, M. Merklein, Journal of Manufacturing and Materials Processing 5 (2021) 25.

Investigation of Different Joining by Forming Strategies when Connecting Different Metals without Auxiliary Elements

D. Römisch, M. Kraus, M. Merklein, Key Engineering Materials 883 (2021) 19–26.

Influence of pin geometry on the joint strength of CFRT-metal hybrid parts with metallic pins

J. Popp, T. Kleffel, D. Drummer, Joining Plastics 15 (2021).

Investigation of the influence of formed, non-rotationally symmetrical pin geometries and their effect on the joint quality of steel and aluminium sheets by direct pin pressing

D. Römisch, M. Kraus, M. Merklein, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications 236 (2022) 1187–1202.

Joining of CFRT/Steel Hybrid Parts via Direct Pressing of Cold Formed Non-Rotational Symmetric Pin Structures

J. Popp, D. Römisch, M. Merklein, D. Drummer, Applied Sciences 12 (2022).

Joining of continuous fiber reinforced thermoplastic/steel hybrid parts via undercutting pin structures and infrared heating

J. Popp, D. Drummer, Journal of Advanced Joining Processes 5 (2022) 100084.

Robustness Analysis of Pin Joining

D. Römisch, C. Zirngibl, B. Schleich, S. Wartzack, M. Merklein, Journal of Manufacturing and Materials Processing 6 (2022).

Pin Extrusion for Mechanical Joining from Orbital Formed Tailored Blanks with Local Material Pre-Distribution

D. Römisch, A. Hetzel, S. Wituschek, M. Lechner, M. Merklein, Journal of Manufacturing and Materials Processing 6 (2022).

Warmforming Flow Pressing Characteristics of Continuous Fibre Reinforced Thermoplastic Composites

B. Gröger, D. Römisch, M. Kraus, J. Troschitz, R. Füßel, M. Merklein, M. Gude, Polymers 14 (2022).

Experimental and Numerical Analysis of Cold Formed Multi Pin Structures Using a Multi-Acting Tool Design

D. Römisch, M. Merklein, in: 2022.

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.R. Bielak, J. Troschitz, Journal of Advanced Joining Processes 5 (2022).

Review on mechanical joining by plastic deformation

G. Meschut, M. Merklein, A. Brosius, D. Drummer, L. Fratini, U. Füssel, M. Gude, W. Homberg, P.A.F. Martins, M. Bobbert, M. Lechner, R. Kupfer, B. Gröger, D. Han, J. Kalich, F. Kappe, T. Kleffel, D. Köhler, C.-M. Kuball, J. Popp, D. Römisch, J. Troschitz, C. Wischer, S. Wituschek, M. Wolf, Journal of Advanced Joining Processes 5 (2022).

Provision of cross-domain knowledge in mechanical joining using ontologies

C. Zirngibl, P. Kügler, J. Popp, C.R. Bielak, M. Bobbert, D. Drummer, G. Meschut, S. Wartzack, B. Schleich, Production Engineering (2022).

Non-destructive testing in versatile joining processes

M. Lechner, T. Borgert, M. Busch, A. Harms, P.K. Holtkamp, D. Römisch, S. Wituschek, F. Kappe, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Show all publications