A02 - Graded, mechanically joined aluminium castings

The realisation of multi-material design in modern automotive construction requires the combination of different materials in body construction. However, this involves the joining of sheet metal as well as extruded profiles with castings. Aluminium is often used as casted material due to its low density plus its excellent mechanical properties. Furthermore, aluminium castings allow a high level of design flexibility combined with a geometry that is suitable for the adapted load as well as cost-effectiveness. Castings are usually produced using the die casting/chill casting process or sand casting. To achieve the desired weight reduction on the one hand and to be able to guarantee the high strength for safety-relevant components, on the other hand, the cast components consist of 85 % – 90 % of a hardenable aluminium alloy of the aluminium-silicon system. The AlSiMg system is especially suitable for a lightweight application in the vehicle body. Since the weldability of such alloys is limited, mechanical joining is an adequate option. For this application, the challenge is to produce a crack-free joint, since the less ductile cast aluminium alloys lead to cracks during the joining process. This issue is being investigated in sub-project A02.

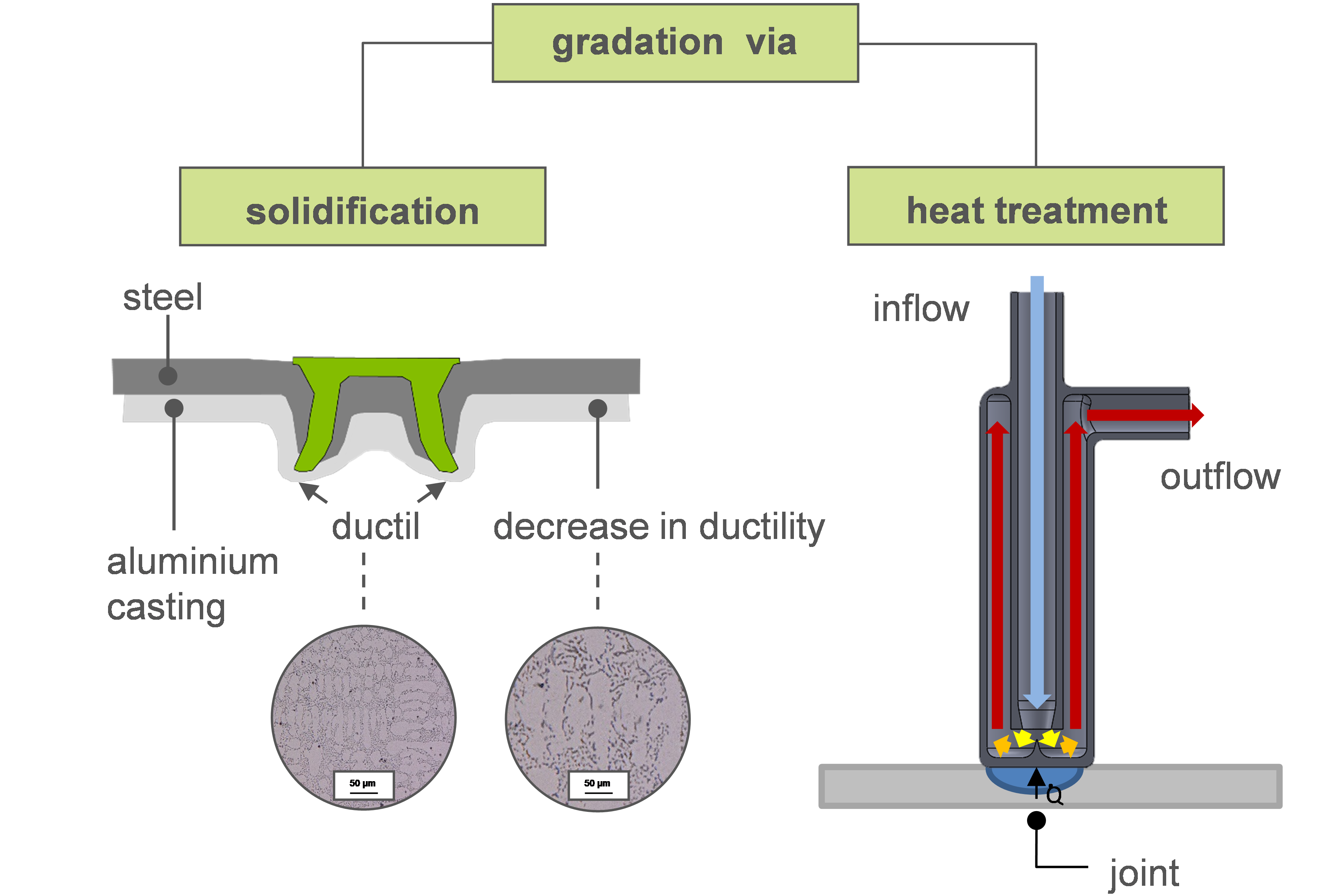

This sub-project aims to produce graded, high-strength and joinable aluminium castings, thereby enabling a crack-free joint in a versatile process chain. Grading the joint locally increases the ductility of the casting, whereby cracking at the joint of cast aluminium components can be reduced or even avoided. As joining methods, clinching and self-piercing riveting are employed, among others. The cast aluminium components are manufactured using the three casting processes “sand casting” and “permanent-mould castings” as well as “twin-roll casting”. On the one hand, the local grading of the castings can be realised via the solidification conditions and, on the other hand, via heat treatment.

The different casting processes exhibit a significant influence on the solidification of the castings for the solidification rate varies between 1 K/s and up to 200 K/s. High solidification rates lead to a finer microstructure, which enhances the ductility and reduces the crack susceptibility. Such a solidification gradation is realised using a temperature-controlled permanent-mould casting tool. Moreover, it is possible to achieve additional grading of the material through local heat treatment.

Veröffentlichungen

Publications

Influence of Nozzle Shape on Near-Surface Segregation Formation During Twin-Roll Casting of Aluminum Strips

O. Grydin, M. Stolbchenko, M. Schaper, in: Light Metals 2020, Cham, 2020, pp. 1039–1044.

Effect of Solidification Rates at Sand Casting on the Mechanical Joinability of a Cast Aluminium Alloy

M. Neuser, O. Grydin, A. Andreiev, M. Schaper, Metals (2021).

Joining suitability of cast aluminium for self-piercing riveting

M. Neuser, F. Kappe, M. Busch, O. Grydin, M. Bobbert, M. Schaper, G. Meschut, T. Hausotte, IOP Conference Series: Materials Science and Engineering (2021).

Experimentelle bruchmechanische Untersuchung eines clinchgeeigneten Bleches aus HCT590X mithilfe einer neuen Probengeometrie

D. Weiß, B. Schramm, M. Neuser, O. Grydin, G. Kullmer, in: 2021, pp. 231–240.

Mechanical Properties and Joinability of AlSi9 Alloy Manufactured by Twin‐Roll Casting

M. Neuser, F. Kappe, J. Ostermeier, J.T. Krüger, M. Bobbert, G. Meschut, M. Schaper, O. Grydin, Advanced Engineering Materials 24 (2022).

Mechanical Properties and Joinability of AlSi9 Alloy Manufactured by Twin‐Roll Casting

M. Neuser, F. Kappe, J. Ostermeier, J.T. Krüger, M. Bobbert, G. Meschut, M. Schaper, O. Grydin, Advanced Engineering Materials 24 (2022).

Influence of heat treatment on the suitability for clinching of the aluminium casting alloy AlSi9

M. Neuser, M. Böhnke, O. Grydin, M. Bobbert, M. Schaper, G. Meschut, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (2022).

Influence of solidification rates and heat treatment on the mechanical performance and joinability of the cast aluminium alloy AlSi10Mg

M. Neuser, O. Grydin, Y. Frolov, M. Schaper, Production Engineering (2022).

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.-R. Bielak, J. Troschitz, Journal of Advanced Joining Processes (2022).

Numerical and Experimental Investigation of Heat Transfer in the Solidification-Deformation Zone During Twin-Roll Casting of Aluminum Strips

O. Grydin, D. Mortensen, M. Neuser, D. Lindholm, H.G. Fjaer, M. Schaper, in: Light Metals 2022, Springer International Publishing, Cham, 2022.

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.R. Bielak, J. Troschitz, Journal of Advanced Joining Processes 5 (2022).

Influence of thermo-mechanical joining process on the microstructure of a hypoeutectic aluminium cast alloy

T. Borgert, M. Neuser, E. Wiens, O. Grydin, W. Homberg, M. Schaper, in: Materials Research Proceedings, Materials Research Forum LLC, 2023, pp. 187–194.

Mechanical and Microstructure Characterisation of the Hypoeutectic Cast Aluminium Alloy AlSi10Mg Manufactured by the Twin-Roll Casting Process

M. Neuser, M. Schaper, O. Grydin, Journal of Manufacturing and Materials Processing 7 (2023).

Thermomechanical Joining of Hypoeutectic Aluminium Cast Plates

T. Borgert, M. Neuser, K.-P. Hoyer, W. Homberg, M. Schaper, Journal of Manufacturing and Materials Processing 7 (2023).

Influence of Shell Material on the Microstructure and Mechanical Properties of Twin-Roll Cast Al-Si-Mg Alloy

O. Grydin, M. Neuser, M. Schaper, in: Conference: ICTP 2023: Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of PlasticityAt: Cannes (France), Springer Nature Switzerland, Cham, 2023.

Mechanical joinability of microstructurally graded structural components manufactured from hypoeutectic aluminium casting alloys

M. Neuser, M.C. Schlichter, K.-P. Hoyer, M. Bobbert, G. Meschut, M. Schaper, 44th Conference of the International Deep Drawing Research Group (IDDRG 2025) 408 (2025).

Mechanical properties and joinability of the near-eutectic aluminium casting alloy AlSi12

M. Neuser, P.K. Holtkamp, K.-P. Hoyer, F. Kappe, S. Yildiz, M. Bobbert, G. Meschut, M. Schaper, The Journal of Materials: Design and Applications, Part L (2025).

Show all publications