B03 - Corrosion modeling for the evaluation of mechanically joined components

In modern lightweight structures, especially in hybrid construction, contact corrosion plays a significant role in evaluating the tolerable loads due to the large number of material combinations, since corrosion can significantly reduce the fatigue strength of joints.

With damage mechanics, a powerful method has developed to predict the failure of joints. Coupled simulations can replace time-consuming experimental tests in conjunction with classical fatigue strength concepts. For damage due to corrosion, only a few descriptions exist so far: these include primarily phenomenologically based approaches; furthermore, the first physically motivated models, such as those based on diffusion equations and reaction kinetics for the considered species have been investigated.

Thus, in a coupled model, the classical mechanical damage can be extended by describing the degradation of the material due to corrosion.

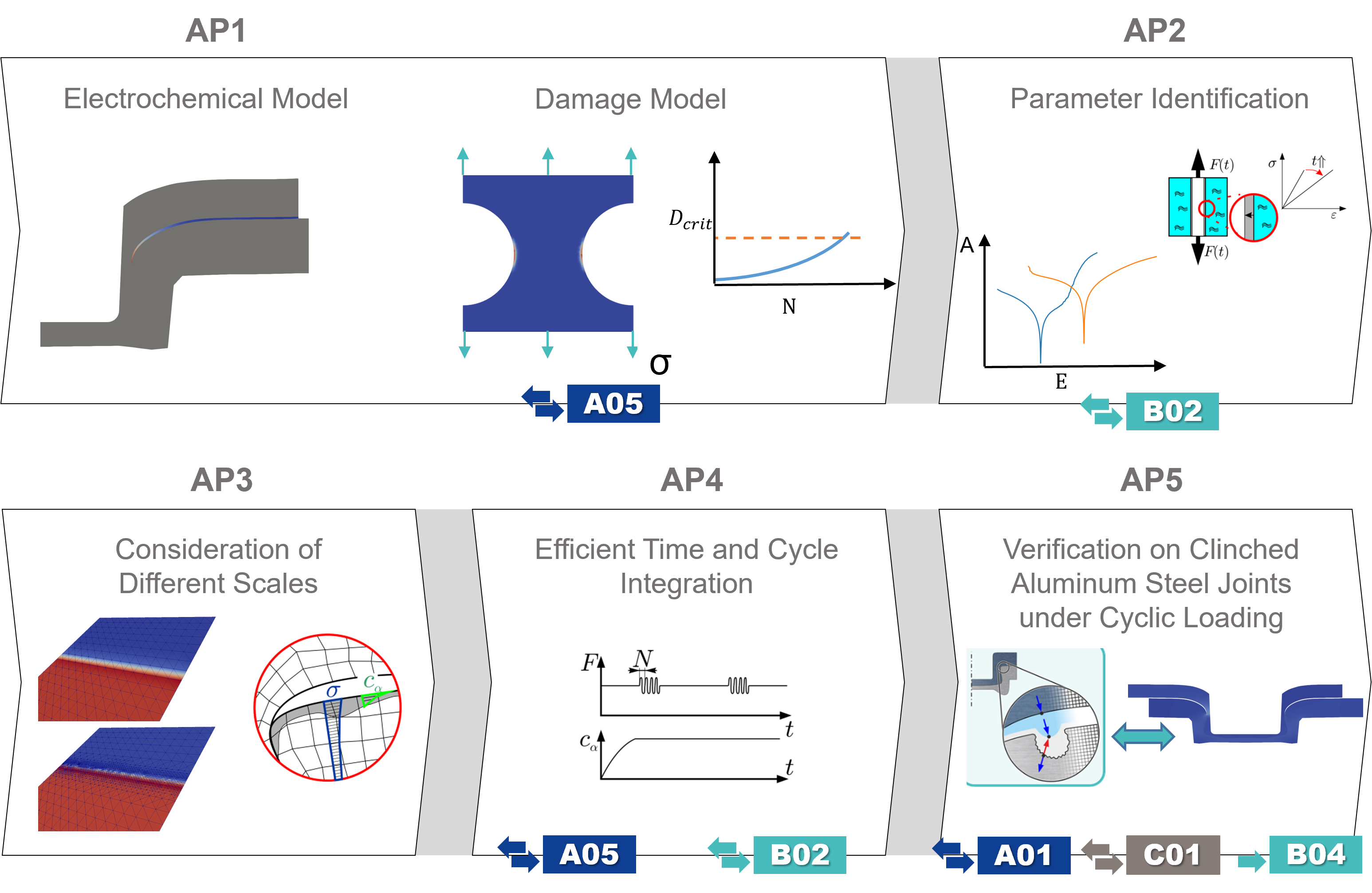

The aim of the present subproject is to combine a classical mechanical damage formulation with contributions from material degradation due to corrosion in order to obtain a closed model that takes into account the influences of corrosion on damage. It is important to consider a full coupling, since particle transport is faster in mechanically damaged areas. Compared to classical fatigue strength, this detailed field approach also offers the advantage that it can correctly represent local corrosion phenomena (contact corrosion) in the region between the joining partners.

The properties of the joined structure and the findings on the condition of the joint after the joining process are then incorporated into the numerical simulation. Likewise, the maximum tolerable corrosion effects based on fracture mechanical investigations must also be taken into account. Together with the experimental partners of the Transregio, model parameters can then be determined and the numerical simulation can be verified. Based on the numerical results, design recommendations - taking corrosion into account - can then be derived together with other subprojects.

Thus, through the close connection to the other projects within the Transregio, the present subproject provides (i) a coupled model for the description of the damage due to both high cyclic loading and contact corrosion, (ii) the material parameters used therein, as well as (iii) effects of the prior damage due to the joining process.

Korrosionsmodellierung

Publications

A First Approach for the Treatment of Galvanic Corrosion and of Load-Bearing Capacity of Clinched Joints

S. Harzheim, C. Steinfelder, T. Wallmersperger, A. Brosius, Key Engineering Materials 883 (2021) 97–104.

A first Model of Fatigue Corrosion of a Metal through Hydrogen Embrittlement

M. Hofmann, Y. Shi, T. Wallmersperger, PAMM 20 (2021).

Corrosion Phenomena and Fatigue Behavior of Clinched Joints: Numerical and Experimental Investigations

S. Harzheim, L. Ewenz, M. Zimmermann, T. Wallmersperger, Journal of Advanced Joining Processes 6 (2022).

A Damage Model for Corrosion Fatigue Due to Hydrogen Embrittlement

Y. Shi, S. Harzheim, M. Hofmann, T. Wallmersperger, in: Material Modeling and Structural Mechanics, Springer International Publishing, Cham, 2022.

Comparison of two mesh-moving techniques for finite element simulations of galvanic corrosion

S. Harzheim, M. Hofmann, T. Wallmersperger, Acta Mechanica 233 (2022) 4427–4439.

Numerical fatigue life prediction of corroded and non-corroded clinched joints

S. Harzheim, M. Hofmann, T. Wallmersperger, Mechanics of Advanced Materials and Structures (2022) 1–6.

A Review on the Modeling of the Clinching Process Chain - Part III: Operational Phase

B. Schramm, S. Harzheim, D. Weiß, T.D. Joy, M. Hofmann, J. Mergheim, T. Wallmersperger, Journal of Advanced Joining Processes (2022).

A Review on the Modeling of the Clinching Process Chain - Part I: Design Phase

B. Schramm, S. Martin, C. Steinfelder, C.R. Bielak, A. Brosius, G. Meschut, T. Tröster, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes 6 (2022).

A Review on the Modeling of the Clinching Process Chain - Part II: Joining Process

B. Schramm, J. Friedlein, B. Gröger, C.R. Bielak, M. Bobbert, M. Gude, G. Meschut, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes (2022).

Show all publications