Method development for mechanical joinability in versatile process chains

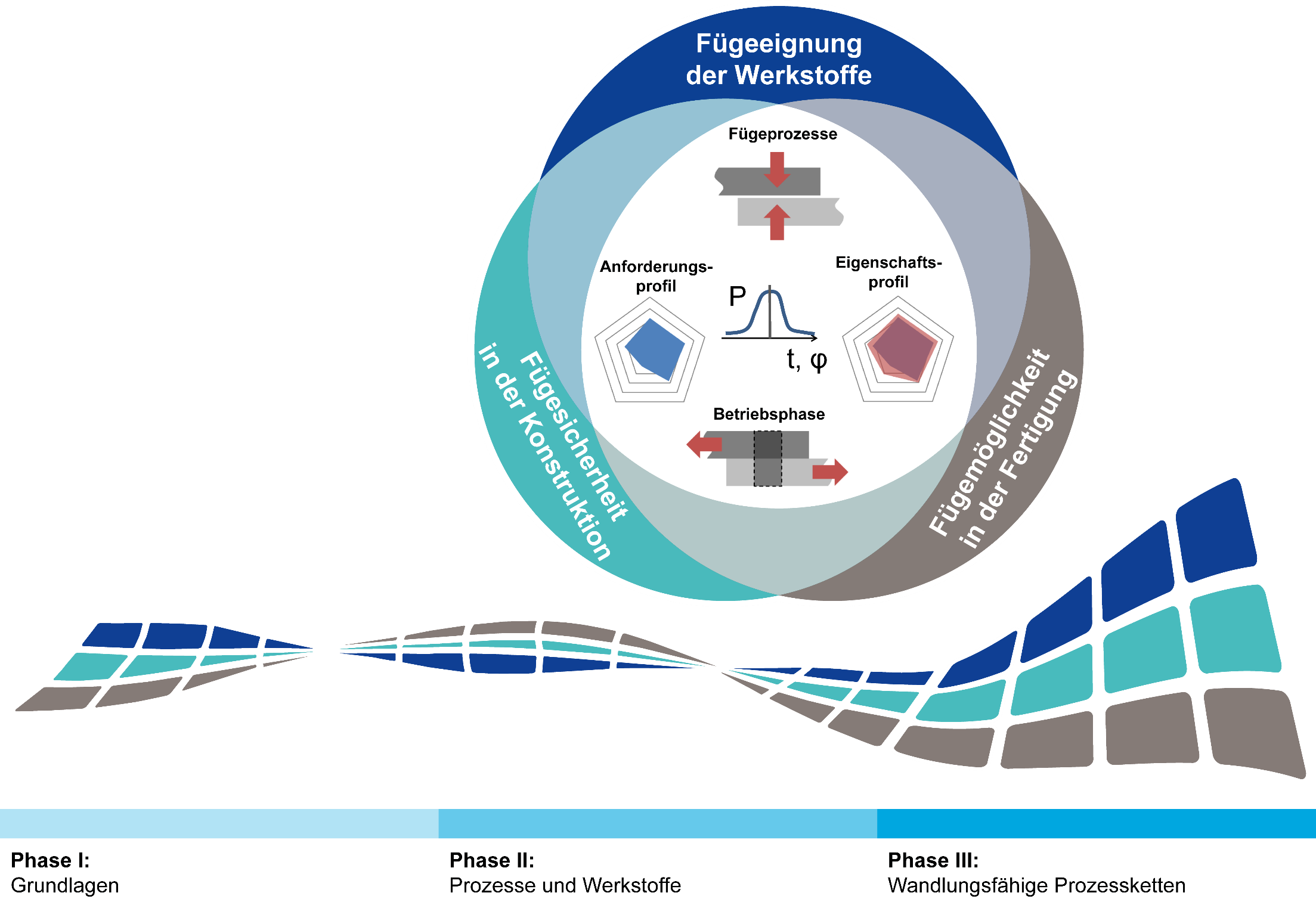

In all areas of product manufacturing, e.g. vehicle construction, machine and plant construction, medical and household appliance technology, constructions made of individual components are usually joined to more or less complex structures with a numerous number of joints. The joinability is the key for efficient production processes of variable structures with shorter model cycles and is increasingly becoming a strategic competitive factor for Germany as a development and production location of products. The growing number of material-geometry-combinations (MGC) requires not only a reliable prognosis of the joinability, but also in particular the versatility of mechanical joining processes. Up to now, mechanical joining processes have been configured to the respective MGC and can only be adapted to external process influences to a very limited extent, which means that they have to be adapted to new MGC at great expense. The vision of the Transregional Collaborative Research Center 285 is to ensure the mechanical joinability in versatile process chains. Using the example of mechanical joints, an interdisciplinary team of researchers is investigating scientific methods for transformability in the three areas of material (joining suitability), design (joining safety) and production (joining possibility) as well as for reliable prognosis and design of the joinability. In the long term, a flexible, transferable and cross-industry design methodology will be available. For new joining tasks, this provides the possibility of selecting the process and designing the joint, creating suitable material solutions and taking into account the interactions between the preceding manufacturing steps and the joint load-bearing capacity. The achievable mechanical properties of the joints can thus be predicted in advance with sufficient accuracy.