A03 - Calculation and evaluation of process-induced structural material phenomena in FRP-metal compounds

The use of fibre-reinforced plastic (FRP) composites with thermoplastic matrix enables the production of lightweight structures within very short cycle times. The specific material properties, in particular formability under heat and anisotropy, enable joining connections of dissimilar joining partners with novel assembly technologies such as hot-formed bolt holes, thermoclinch connections, thermally assisted clinch joints, embedded inserts or auxiliary-free pin connections. The associated joining processes and their preparation steps are accompanied by successive local changes in the material structure of the FRP. For example, in the case of thermoformed holes in thermoplastic composites, fibres are displaced in the joining zone and thus the reinforcement structure is locally compressed, resulting in locally varying fibre volume fractions and fibre angles as well as displacements of the matrix material. This locally varying material structure effect the load-bearing behaviour of the joint results from a multitude of material and design-technological influencing parameters. The resultant material structure has been determined by means of resource-consuming structural investigations of the joining zone. Due to the limitation of the process simulation for FRP a prediction of the accurate material structure leads to a lack of information in the design process. The numerical analysis of the load-bearing capacity is carried out under the assumption of an idealised reinforcement structure and reduced single-layer characteristic values. This means that considerable potential with regard to the specific load-bearing capacity of the joint and the flexible adaptation of the joining process is currently not being exploited.

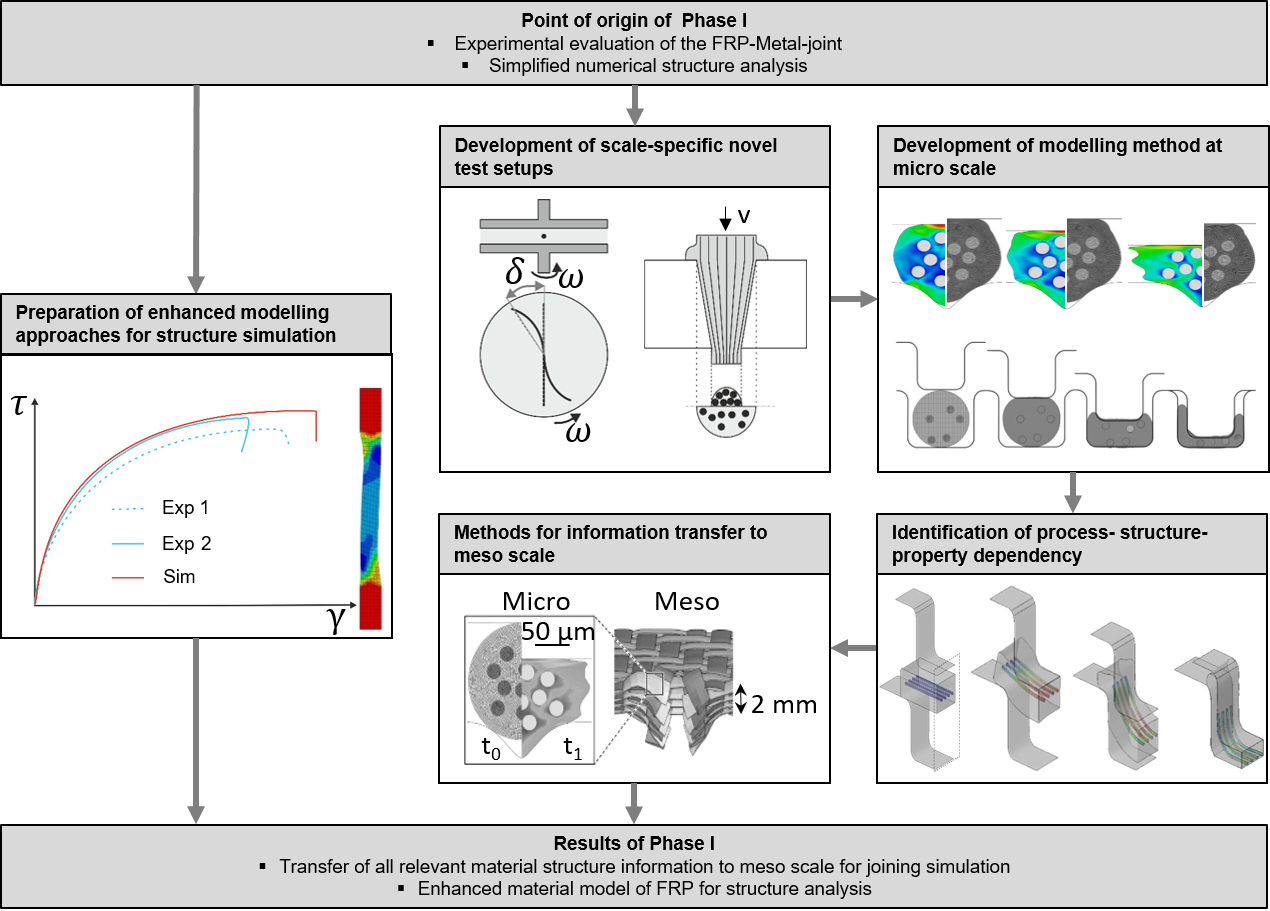

In sub-project A03 a continuous simulation chain from the joining process to the structural-mechanical evaluation of FRP/metal joints is to be developed. The development has to consider a predictable joinability, an improved utilisation of the load transfer potential of thermoplastic composite-metal structures as well as the associated adaptability of the process chain. For this purpose, a cross-scale approach will be developed. This enables the prediction of the process-related phenomena at microscopic material structure. Furthermore, the structure can be taken into account within the framework of macroscopic load-bearing capacity analyses of hot-formed FRP joining elements at the composite level.

For this purpose, a method based on the combined Euler-Lagrangian approach for modelling and calculating the resulting material structure at micro scale of the FRP from the respective joining process are evolved. The enhanced phenomenological understanding of joining phenomena as well as the physically based approach are the basis for the material-specific flexibilisation of the process chains considered in the TR. Thus, the method enables a focused construction and design process by taken into account the varying geometry, material and process parameters and also their influence on the resulting joint.

In addition to preparate established modelling approaches at single layer level for the simulation of the mesoscopically homogenised composite behaviour for FRP/metal joints, phase I focuses in particular on the description of the process-related single fibre deformations on the basis of experimental tests at the microscale. For this process analysis, novel test environments are developed that allow a detailed investigation of the interactions of single fibres as well as fibre bundles and molten matrix. The initial and boundary conditions are applied differently. The different deformation and deflection behaviour of fibres and matrix is captured. Furthermore, direction and fibre volume content-dependent permeabilities are then derived, which can then be used to describe the hot forming process across scales.

Werkstoffgerechtes Fügen FKV

Veröffentlichungen

Publications

Characterization and Numerical Modelling of Through-Thickness Metallic-Pin-Reinforced Fibre/Thermoplastic Composites under Bending Loading

H. Böhm, H. Zhang, B. Gröger, A. Hornig, M. Gude, Journal of Composites Science 4 (2020) 188.

Experimental and Numerical Studies on the Deformation of a Flexible Wire in an Injection Moulding Process

D. Köhler, B. Gröger, R. Kupfer, A. Hornig, M. Gude, Procedia Manufacturing 47 (2020) 940–947.

Clinching of Thermoplastic Composites and Metals—A Comparison of Three Novel Joining Technologies

B. Gröger, J. Troschitz, J. Vorderbrüggen, C. Vogel, R. Kupfer, G. Meschut, M. Gude, Materials 14 (2021) 2286.

Computed tomography investigation of the material structure in clinch joints in aluminium fibre-reinforced thermoplastic sheets

B. Gröger, D. Köhler, J. Vorderbrüggen, J. Troschitz, R. Kupfer, G. Meschut, M. Gude, Production Engineering (2021).

Modelling of thermally supported clinching of fibre-reinforced thermoplastics: Approaches on mesoscale considering large deformations and fibre failure

B. Gröger, A. Hornig, A. Hoog, M. Gude, ESAFORM 2021 - 24th International Conference on Material Forming (2021).

Temperature dependent modelling of fibre-reinforced thermoplastic organo-sheet material for forming and joining process simulations

B. Gröger, A. Hornig, A. Hoog, M. Gude, Key Engineering Materials 883 KEM (2021) 49.

Computed tomography investigation of the material structure in clinch joints in aluminium fibre-reinforced thermoplastic sheets

B. Gröger, D. Köhler, J. Vorderbrüggen, J. Troschitz, R. Kupfer, G. Meschut, M. Gude, Production Engineering 16 (2021) 203–212.

Joining Processes for Fibre-Reinforced Thermoplastics: Phenomena and Characterisation

J. Troschitz, B. Gröger, V. Würfel, R. Kupfer, M. Gude, Materials 15 (2022).

Forming process induced material structure of fibre-reinforced thermoplastics - Experimental and numerical investigation of a bladder-assisted moulding process

B. Gröger, V. Würfel, A. Hornig, M. Gude, Journal of Advanced Joining Processes 5 (2022).

Characterisation of Fibre Bundle Deformation Behaviour—Test Rig, Results and Conclusions

A. Borowski, B. Gröger, R. Füßel, M. Gude, Journal of Manufacturing and Materials Processing 6 (2022).

Warmforming Flow Pressing Characteristics of Continuous Fibre Reinforced Thermoplastic Composites

B. Gröger, D. Römisch, M. Kraus, J. Troschitz, R. Füßel, M. Merklein, M. Gude, Polymers 14 (2022).

A Data Driven Modelling Approach for the Strain Rate Dependent 3D Shear Deformation and Failure of Thermoplastic Fibre Reinforced Composites: Experimental Characterisation and Deriving Modelling Parameters

J. Gerritzen, A. Hornig, B. Gröger, M. Gude, Journal of Composites Science 6 (2022).

Modelling and Simulation Strategies for Fluid–Structure-Interactions of Highly Viscous Thermoplastic Melt and Single Fibres—A Numerical Study

B. Gröger, J. Wang, T. Bätzel, A. Hornig, M. Gude, Materials 15 (2022).

Review on mechanical joining by plastic deformation

G. Meschut, M. Merklein, A. Brosius, D. Drummer, L. Fratini, U. Füssel, M. Gude, W. Homberg, P.A.F. Martins, M. Bobbert, M. Lechner, R. Kupfer, B. Gröger, D. Han, J. Kalich, F. Kappe, T. Kleffel, D. Köhler, C.-M. Kuball, J. Popp, D. Römisch, J. Troschitz, C. Wischer, S. Wituschek, M. Wolf, Journal of Advanced Joining Processes 5 (2022).

A Review on the Modeling of the Clinching Process Chain - Part II: Joining Process

B. Schramm, J. Friedlein, B. Gröger, C.R. Bielak, M. Bobbert, M. Gude, G. Meschut, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes (2022).

Show all publications