B04 - Crack growth in joined structures

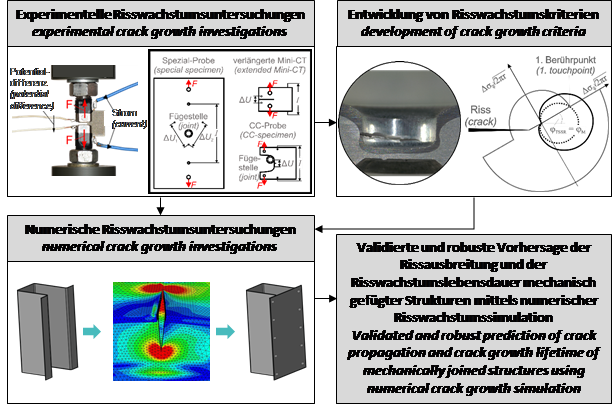

The use of novel manufacturing processes requires the design of components in terms of static strength, fatigue strength, crack sensitivity and crack growth life, which leads to the need for crack propagation investigations of cracked structures. The starting point for these investigations is damage resulting from the joining process as well as initial cracks that occur during operation as a result of fatigue and/or corrosion. Mechanical joints are characterized in particular by contact between the parts to be joined, high stress concentrations, heterogeneous material states, residual stresses and multi-axial, out-of-phase stress states. These factors can also influence the propagation of a crack. At the same time, a wide range of material-geometry or anxillary joining part-tool combinations is present due to the versatility of the process chains. The content of subproject B04 is to investigate crack growth based on technical initial cracks, taking into account the above-mentioned factors and the versatility of the process chains that occur in mechanically joined structures.

The aims of the subproject are the characterization of the fracture-mechanical property profile of mechanically joined structures as well as the consistent description of the crack propagation process and the occurrence of the unstable failure under consideration of the local stress and material conditions. The synergetic use of the methodological competences "experimental crack growth investigations", "theoretical-analytical modeling of crack growth" and "numerical simulation of crack growth" enables a comprehensive and viable consideration of the fracture-mechanical behavior of joined structures in use and a contribution to the holistic description of the joinability under consideration of the versatility process chains. For this purpose, the fracture-mechanical material characteristics of the base materials, the formed joining parts and the joined structures are investigated. In addition, the main material- and process-related influencing factors and their effects on the crack propagation behavior are identified. Fracture mechanical concepts for the prediction of crack growth have to be extended under certain circumstances by these findings for mechanically joined structures. In addition, the simulation program ADAPCRACK3D developed by FAM will be extended so that crack growth can be simulated automatically starting from a defect and the remaining service life can be determined for mechanically joined structures. The investigations of crack growth are intended to provide information on the design of the joined structure and on the significance of the material, geometric and process variable variations that are essential due to the versatility of the joining processes, in order to prevent the propagation of a crack and unstable failure in mechanically joined structures.

Risswachstum

Veröffentlichungen

Publications

Development of a special specimen geometry for the experimental determination of fracture mechanical parameters of clinchable metal sheets

D. Weiß, B. Schramm, G. Kullmer, 28 (2020) 2335–2341.

Experimental and numerical preliminary investigations of the base material and preformed components regarding fatigue crack growth in joined structures

D. Weiß, B. Schramm, G. Kullmer, in: 2020.

Numerical and Experimental Fracture Mechanical Investigations of Clinchable Sheet Metals Made of HCT590X

D. Weiß, B. Schramm, G. Kullmer, Key Engineering Materials 883 (2021) 127–132.

Holistic investigation chain for the experimental determination of fracture mechanical material parameters with special specimens

D. Weiß, B. Schramm, G. Kullmer, Production Engineering (2021).

Entwicklung einer Methode zur differenzierten Messung des Wachstums der Rissenden von Innenrissen mit der Elektropotentialmethode

G. Kullmer, D. Weiß, B. Schramm, in: 2021, pp. 107–116.

Experimentelle bruchmechanische Untersuchung eines clinchgeeigneten Bleches aus HCT590X mithilfe einer neuen Probengeometrie

D. Weiß, B. Schramm, M. Neuser, O. Grydin, G. Kullmer, in: 2021, pp. 231–240.

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.R. Bielak, J. Troschitz, Journal of Advanced Joining Processes 5 (2022).

Fracture mechanical investigation of preformed metal sheets using a novel CC-specimen

D. Weiß, B. Schramm, in: Procedia Structural Integrity, Elsevier BV, 2022, pp. 879–885.

Further Development of 3D Crack Growth Simulation Program to Include Contact Loading Situations

T.D. Joy, D. Weiß, B. Schramm, G. Kullmer, Applied Sciences 12 (2022).

Influence of plane mixed-mode loading on the kinking angle of clinchable metal sheets

D. Weiß, B. Schramm, G. Kullmer, in: Procedia Structural Integrity, Elsevier BV, 2022, pp. 139–147.

A Review on the Modeling of the Clinching Process Chain - Part III: Operational Phase

B. Schramm, S. Harzheim, D. Weiß, T.D. Joy, M. Hofmann, J. Mergheim, T. Wallmersperger, Journal of Advanced Joining Processes (2022).

Development of a method for the separate measurement of the growth of internal crack tips by means of the potential drop method

G. Kullmer, D. Weiß, B. Schramm, Engineering Fracture Mechanics (2022).

Fracture mechanical evaluation of the material HCT590X

B. Schramm, D. Weiß, Materials Testing 64 (2022) 1437–1449.

A Review on the Modeling of the Clinching Process Chain - Part I: Design Phase

B. Schramm, S. Martin, C. Steinfelder, C.R. Bielak, A. Brosius, G. Meschut, T. Tröster, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes 6 (2022).

A Review on the Modeling of the Clinching Process Chain - Part II: Joining Process

B. Schramm, J. Friedlein, B. Gröger, C.R. Bielak, M. Bobbert, M. Gude, G. Meschut, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes (2022).

Bruchmechanische Untersuchung des Dualphasenstahls HCT590X unter Temperatureinfluss

D. Weiß, T. Duffe, M. Buczek, G. Kullmer, B. Schramm, in: Deutscher Verband für Materialforschung und -prüfung e.V., 2023.

An alternative and robust formulation of the fatigue crack growth rate curve for long cracks

G. Kullmer, D. Weiß, B. Schramm, Engineering Fracture Mechanics 296 (2024).

Weiterentwicklung des Exponentialansatzes zur Beschreibung von Rissfortschrittskurven

G. Kullmer, D. Weiß, B. Schramm, in: Deutscher Verband für Materialforschung und –prüfung e.V., 2024.

Show all publications