B05 - Design of versatile joints

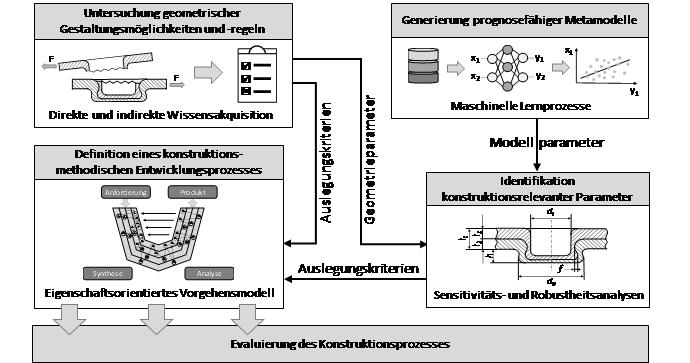

Newly challenges of varying material-geometry-combinations and the increasing demand of lightweight designs require not only reliable prediction models for the determination of the joining possibility, safety and suitability but also the consideration of versatile process chains. Therefore, the sub-project B05 pursues the goal of developing a comprehensive design methodology for the dimensioning and optimization of individual joining components in combination with the selection of suitable mechanical joining techniques taking varying input parameters into account. For this purpose, predictive meta-models will be developed which involve a large number of process parameters as well as different material and sheet thickness combinations in order to estimate mechanical properties of the joints in advance with a sufficient accuracy. However, since the carrying out of experimentally or numerical studies is highly cost- and time-intensive, it is crucial to identify efficient methods for the sufficient description of varying input parameters and to obtain reliable regression models based on limited databases. Thus, a main challenge is to keep the configuration effort manageable on the one hand and on the other hand, to remain the design methodology adaptable enough to be able to design different mechanical joining processes flexibly and robustly for the application in versatile process chains. Additionally, the application of sensitivity and robustness analyses enables the identification of relevant and non-relevant joining parameters based on their impact on specific geometrical joint characteristics and load-bearing capacities. As a result, it is possible to significantly reduce the complexity of the initially trained models and to derive design formulas. After the completion of the first project phase, the novel design methodology not only provides a procedure for the efficient selection of mechanical joining processes but also a knowledge-and data-based dimensioning and optimization of the particular joints.

Konstruktive Auslegung

Publications

Potentiale datengestützter Methoden zur Gestaltung und Optimierung mechanischer Fügeverbindungen

C. Zirngibl, B. Schleich, S. Wartzack, Proceedings of the 31st Symposium Design for X (DFX2020) (2020).

Data-driven analysis of cold-formed pin structure characteristics in the context of versatile joining processes

D. Römisch, C. Zirngibl, B. Schleich, S. Wartzack, M. Merklein, IOP Conference Series: Materials Science and Engineering 1157 (2021) 012077.

Approach for the automated and data-based design of mechanical joints

C. Zirngibl, B. Schleich, S. Wartzack, Proceedings of the Design Society 1 (2021) 521.

Application of reinforcement learning for the optimization of clinch joint characteristics

C. Zirngibl, F. Dworschak, B. Schleich, S. Wartzack, Production Engineering (2021).

Approach for the automated analysis of geometrical clinch joint characteristics

C. Zirngibl, B. Schleich, Key Engineering Materials 883 KEM (2021) 105.

Knowledge and Data-Based Design and Dimensioning of Mechanical Joining Connections

C. Zirngibl, C. Sauer, B. Schleich, S. Wartzack, in: Volume 2: 42nd Computers and Information in Engineering Conference (CIE), American Society of Mechanical Engineers, 2022.

Estimation of Clinch Joint Characteristics Based on Limited Input Data Using Pre-Trained Metamodels

C. Zirngibl, B. Schleich, S. Wartzack, AI 3 (2022) 990–1006.

Robustness Analysis of Pin Joining

D. Römisch, C. Zirngibl, B. Schleich, S. Wartzack, M. Merklein, Journal of Manufacturing and Materials Processing 6 (2022).

Robust estimation of clinch joint characteristics based on data-driven methods

C. Zirngibl, B. Schleich, S. Wartzack, The International Journal of Advanced Manufacturing Technology (2022).

Provision of cross-domain knowledge in mechanical joining using ontologies

C. Zirngibl, P. Kügler, J. Popp, C.R. Bielak, M. Bobbert, D. Drummer, G. Meschut, S. Wartzack, B. Schleich, Production Engineering (2022).

Determining the influence of different process parameters on the versatile self-piercing riveting process using numerical methods

F. Kappe, C. Zirngibl, B. Schleich, M. Bobbert, S. Wartzack, G. Meschut, Journal of Manufacturing Processes 84 (2022) 1438–1448.

Methodical approach for the design and dimensioning of mechanical clinched assemblies

C. Zirngibl, S. Martin, C. Steinfelder, B. Schleich, T. Tröster, A. Brosius, S. Wartzack, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Influence of process variations on clinch joint characteristics considering the effect of the nominal tool design

C. Zirngibl, S. Goetz, S. Wartzack, Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering (2024).

Approach for the Reliable and Virtual Design of Mechanical Joints in an Uncertain Environment

J.-M. Einwag, S. Goetz, S. Wartzack, in: DS 133: Proceedings of the 35th Symposium Design for X (DFX2024), The Design Society, 2024.

Impact of the parameter distribution on the predictive quality of metamodels for clinch joint properties

J.-M. Einwag, Y. Mayer, S. Goetz, S. Wartzack, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Show all publications