C02 - Versatile joining with a fastener

Due to economic and ecological requirements and the associated trend towards lightweight construction, mechanical pre-hole-free joining technologies are becoming increasingly important. New methods and processes for the production of versatile and customised joints are essential due to the increasing use of high-strength and

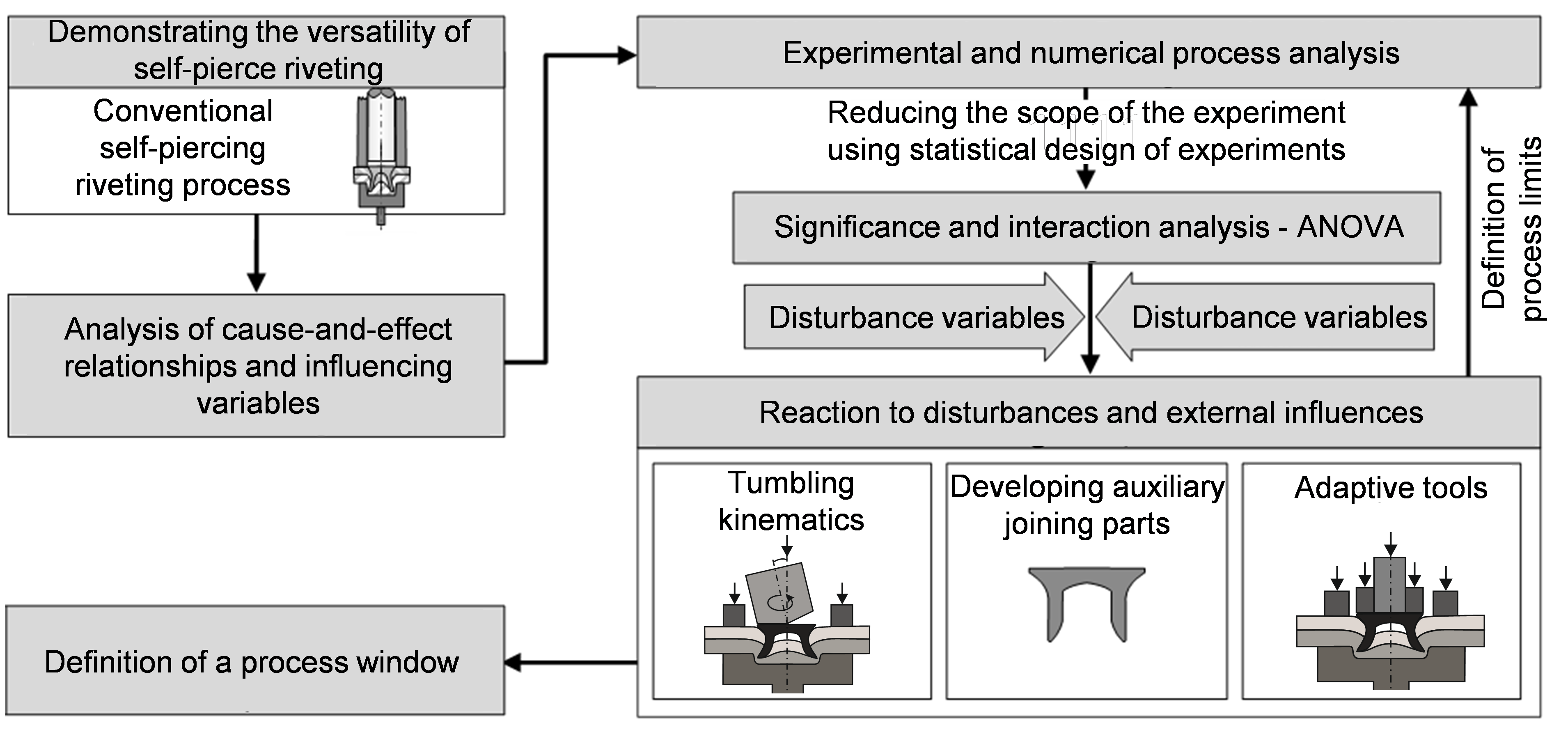

ultra-high-strength materials as well as an increasing number of variants. The limited possibilities for reacting to these changes require new strategies to be developed in order to increase the versatility of mechanical joining technology with adaptive tools, auxiliary joining parts and process kinematics. The aim of the sub-project is therefore to increase the versatility of the self-pierce riveting process by means of universal auxiliary joining elements and in-situ process control. Hereby both process-side disturbance variable and process parameter fluctuations as well as unscheduled changes in the boundary conditions lose their significance. To achieve this, two solution strategies are being pursued that complement each other synergistically. The approach concerns the description of an adaptive, linear process control in order to analyse the mutability of the auxiliary joining part with regard to additional intervention possibilities as well as the process-safe production of a customised joint by forming and inserting self-pierce rivet elements through a tumbling process. Parallel to the analysis of the tumbling process, a disturbance and process variable analysis within a conventional self-pierce riveting process is carried out in order to identify internal and external influencing factors. In addition, effects on the joining quality with regard to the possible load bearing capacity can be analysed. The development of the

self-pierce riveting joining part represents a further approach to increasing versatility, which is based on a geometric, material and functional adaptation of the auxiliary joining parts. In this context, the simulation of the joining process represents an important part of the development process and supports the derivation of an in-depth understanding of the process, which in turn supports the selection of suitable rivet element variants. Finally, adaptive tools are to be conceptually developed that are based on driven active elements and allow individual adaptation of the tool configuration to the joining point.

Wandlungsfähiges Fügen

Publications

Test Method for Friction Characterization of Rivets

S. Wituschek, C.M. Kuball, M. Merklein, M. Lechner, Defect and Diffusion Forum 404 (2020) 132–137.

Investigation of influencing parameters on the joint formation of the self-piercing riveting process

F. Kappe, S. Wituschek, M. Lechner, M. Bobbert, G. Meschut, M. Merklein, in: 2020.

Inverse parameter identification of an anisotropic plasticity model for sheet metal

J. Friedlein, S. Wituschek, M. Lechner, J. Mergheim, P. Steinmann, IOP Conference Series: Materials Science and Engineering 1157 (2021) 012004.

Friction Characterisation for a Tumbling Self-Piercing Riveting Process

S. Wituschek, M. Lechner, Key Engineering Materials 883 (2021) 27–34.

Material characterisation methods for a tumbling self-piercing riveting process

S. Wituschek, M. Lechner, ESAFORM 2021 (2021).

Joining suitability of cast aluminium for self-piercing riveting

M. Neuser, F. Kappe, M. Busch, O. Grydin, M. Bobbert, M. Schaper, G. Meschut, T. Hausotte, IOP Conference Series: Materials Science and Engineering (2021).

Influence of rivet length on joint formation on self-piercing riveting process considering further process parameters

F. Kappe, C.R. Bielak, V. Sartisson, M. Bobbert, G. Meschut, in: ESAFORM 2021, University of Liege, 2021.

Influence of various procedures for the determination of flow curves on the predictive accuracy of numerical simulations for mechanical joining processes

M. Böhnke, F. Kappe, M. Bobbert, G. Meschut, Materials Testing 63 (2021) 493–500.

New Approach for Versatile Self Piercing Riveting: Joining System and Auxiliary Part

F. Kappe, M. Bobbert, G. Meschut, Key Engineering Materials 883 (2021) 3–10.

Investigation of the influence of varying tumbling strategies on a tumbling self-piercing riveting process

S. Wituschek, F. Kappe, M. Lechner, Production Engineering (2021).

Mechanical Properties and Joinability of AlSi9 Alloy Manufactured by Twin‐Roll Casting

M. Neuser, F. Kappe, J. Ostermeier, J.T. Krüger, M. Bobbert, G. Meschut, M. Schaper, O. Grydin, Advanced Engineering Materials 24 (2022).

Investigation of the influence of the tumbling angle on a tumbling self-piercing riveting process

S. Wituschek, M. Lechner, Production Engineering (2022).

Pin Extrusion for Mechanical Joining from Orbital Formed Tailored Blanks with Local Material Pre-Distribution

D. Römisch, A. Hetzel, S. Wituschek, M. Lechner, M. Merklein, Journal of Manufacturing and Materials Processing 6 (2022).

Versatile tool design for a tumbling self-piercing riveting process

S. Wituschek, M. Lechner, in: 2022.

Mechanical Properties and Joinability of AlSi9 Alloy Manufactured by Twin‐Roll Casting

M. Neuser, F. Kappe, J. Ostermeier, J.T. Krüger, M. Bobbert, G. Meschut, M. Schaper, O. Grydin, Advanced Engineering Materials 24 (2022).

Clinching of Aluminum Materials – Methods for the Continuous Characterization of Process, Microstructure and Properties

R. Kupfer, D. Köhler, D. Römisch, S. Wituschek, L. Ewenz, J. Kalich, D. Weiß, B. Sadeghian, M. Busch, J.T. Krüger, M. Neuser, O. Grydin, M. Böhnke, C.R. Bielak, J. Troschitz, Journal of Advanced Joining Processes 5 (2022).

Review on mechanical joining by plastic deformation

G. Meschut, M. Merklein, A. Brosius, D. Drummer, L. Fratini, U. Füssel, M. Gude, W. Homberg, P.A.F. Martins, M. Bobbert, M. Lechner, R. Kupfer, B. Gröger, D. Han, J. Kalich, F. Kappe, T. Kleffel, D. Köhler, C.-M. Kuball, J. Popp, D. Römisch, J. Troschitz, C. Wischer, S. Wituschek, M. Wolf, Journal of Advanced Joining Processes 5 (2022).

Geometric and mechanical joint characterization of conventionally and tumbled self-piercing riveting joints

S. Wituschek, F. Kappe, G. Meschut, M. Lechner, Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (2022).

Mechanical Properties and Joinability of AlSi9 Alloy Manufactured by Twin‐Roll Casting

M. Neuser, F. Kappe, J. Ostermeier, J.T. Krüger, M. Bobbert, G. Meschut, M. Schaper, O. Grydin, Advanced Engineering Materials 24 (2022).

Joining of multi-material structures using a versatile self-piercing riveting process

F. Kappe, S. Wituschek, M. Bobbert, M. Lechner, G. Meschut, Production Engineering (2022).

Numerical Investigation of the Influence of a Movable Die Base on Joint Formation in Semi-tubular Self-piercing Riveting

F. Kappe, S. Wituschek, V. de Pascalis, M. Bobbert, M. Lechner, G. Meschut, in: Materials Design and Applications IV, Springer International Publishing, Cham, 2022.

Determining the influence of different process parameters on the versatile self-piercing riveting process using numerical methods

F. Kappe, C. Zirngibl, B. Schleich, M. Bobbert, S. Wartzack, G. Meschut, Journal of Manufacturing Processes 84 (2022) 1438–1448.

Increasing flexibility of self-piercing riveting by reducing tool–geometry combinations using cluster analysis in the application of multi-material design

F. Kappe, L. Schadow, M. Bobbert, G. Meschut, Proceedings of the Institution of Mechanical Engineers Part L Journal of Materials Design and Applications (2022).

Determining the properties of multi‑range semi‑tubular self‑piercing riveted joints

F. Kappe, S. Wituschek, M. Bobbert, G. Meschut, Production Engineering (2022).

Dynamic conformity assessment for joining force monitoring using Bayes filters

L. Butzhammer, F. Kappe, G. Meschut, T. Hausotte, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Combination of versatile self-piercing riveting processes

S. Wituschek, F. Kappe, G. Meschut, M. Lechner, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Versatile self-piercing riveting with a tumbling superimposed punch

S. Wituschek, L. Elbel, M. Lechner, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Mechanical properties and joinability of the near-eutectic aluminium casting alloy AlSi12

M. Neuser, P.K. Holtkamp, K.-P. Hoyer, F. Kappe, S. Yildiz, M. Bobbert, G. Meschut, M. Schaper, The Journal of Materials: Design and Applications, Part L (2025).

Analysis of the binding mechanisms depending on versatile process variants of self-piercing riveting

S. Lüder, P.K. Holtkamp, S. Wituschek, M. Bobbert, G. Meschut, M. Lechner, H.C. Schmale, in: G. Meschut, M. Bobbert, J. Duflou, L. Fratini, H. Hagenah, P.A.F. Martins, M. Merklein, F. Micari (Eds.), Materials Research Proceedings, Materials Research Forum LLC, Millersville, 2025, pp. 101–108.

Simulation of the joining process of graded hardened multi-range capable rivets

P.K. Holtkamp, C.R. Bielak, M. Bobbert, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Integration of multiple-linear and tumbling kinematics into self-piercing riveting

P.K. Holtkamp, S. Wituschek, M. Lechner, G. Meschut, MATEC Web of Conferences 408 (2025).

Non-destructive testing in versatile joining processes

M. Lechner, T. Borgert, M. Busch, A. Harms, P.K. Holtkamp, D. Römisch, S. Wituschek, F. Kappe, in: Materials Research Proceedings, Materials Research Forum LLC, 2025.

Show all publications