A05 - Damage modelling for the simulation of mechanical joining processes

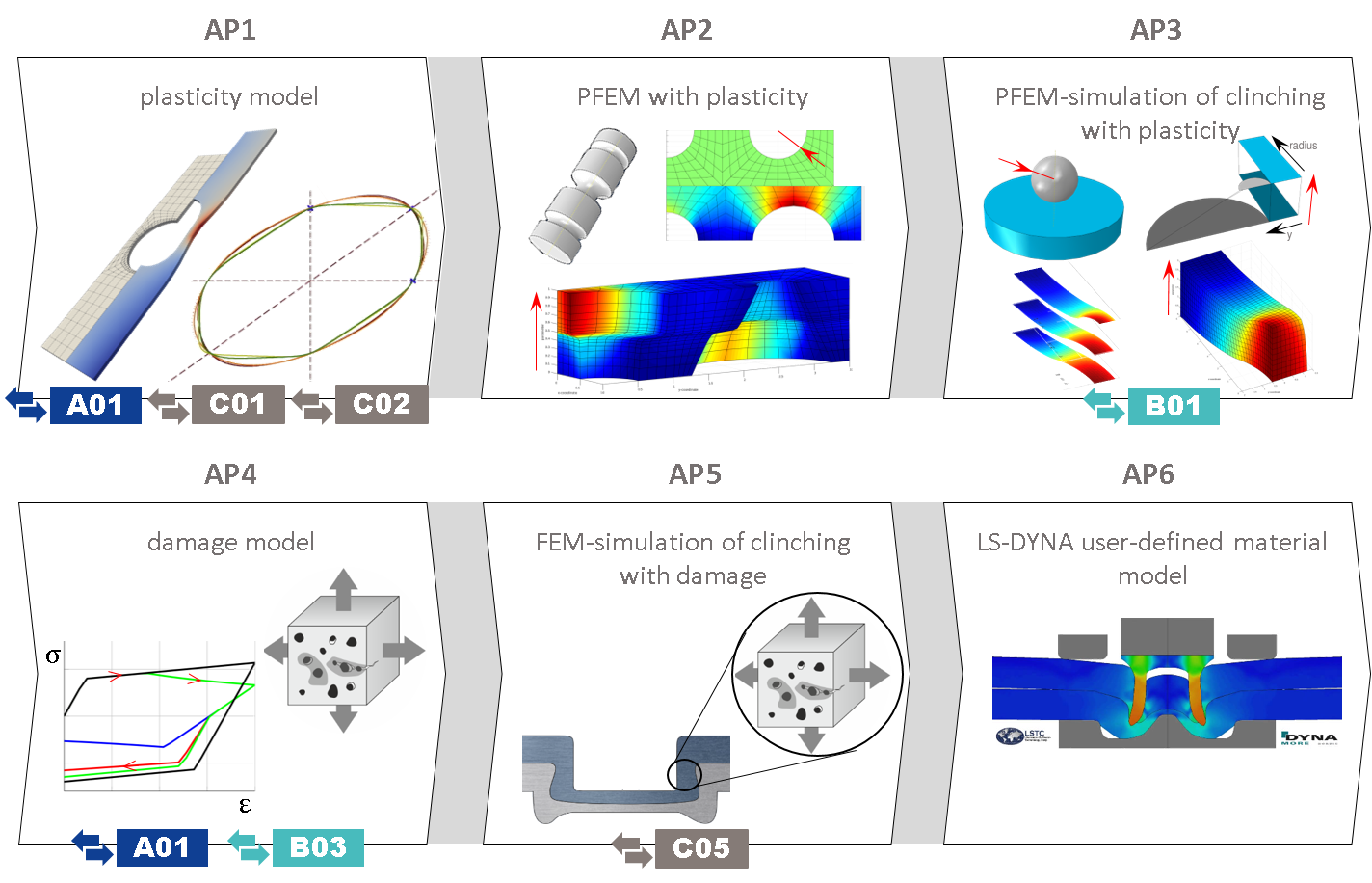

The subproject deals with the modelling and simulation of plasticity and damage during mechanical joining processes in the context of the intended versatility of the processes. On the one hand, material models are developed, numerically implemented robustly and efficiently, and validated experimentally. On the other hand, a numerical method, the so-called Parametric Finite Element Method (PFEM), is developed further, which enables the efficient computation of a large number of material-geometry-combinations and thus represents the ideal solution method for the simulation of versatile processes.

The mechanical joining processes considered in the TRR are accompanied by very large local inelastic deformations. In particular, this results in a strong coupling of finite plasticity and damage. For a better understanding of these mesostructural phenomena occurring during the joining process, suitable material models and their use in the process simulation are indispensable. The development of these material models and their application to a virtual optimisation of the process control are key aspects of this project.

Moreover, the considered mechanical joining processes, such as clinching or self-pierce riveting, are characterised by high demands on the versatility. Targeted changes within the process chain – concerning the semi-finished product, the joint or the joining process – should be possible. The process simulation ought to consider these requirements for versatility and ideally consider such variations from the start. This results in the second focus of the present subproject. The PFEM is extended to include plasticity and damage and is used to simulate mechanical joining processes. In addition to the usual physical coordinates discretising the space, the PFEM introduces additional parametric coordinates that represent one or more geometric or material parameters of the joint. The solution of this higher-dimensional problem simultaneously and very efficiently provides the solutions for continuous variations (instead of a very time-consuming discrete sampling) of these parameters and thus allows a direct comparison of different process variants in light of their versatility.

In summary, the goal of subproject A05 are (i) the physically non-linear and geometrically exact material modelling of coupled plasticity and damage, (ii) their physically motivated regularisation and (iii) the numerical implementation of the models for process simulation within the PFEM to account for the desired versatility of the joining processes.

Schädigungsmodellierung

Publications

Inverse parameter identification of an anisotropic plasticity model for sheet metal

J. Friedlein, S. Wituschek, M. Lechner, J. Mergheim, P. Steinmann, IOP Conference Series: Materials Science and Engineering 1157 (2021) 012004.

Stochastic local FEM for computational homogenization of heterogeneous materials exhibiting large plastic deformations

D. Pivovarov, J. Mergheim, K. Willner, P. Steinmann, Computational Mechanics (2021).

Anisotropic plasticity‐damage material model for sheet metal — Regularised single surface formulation

J. Friedlein, J. Mergheim, P. Steinmann, PAMM 21 (2021).

A finite plasticity gradient-damage model for sheet metals during forming and clinching

J. Friedlein, J. Mergheim, P. Steinmann, Key Engineering Materials 883 KEM (2021) 57.

Parametric FEM for computational homogenization of heterogeneous materials with random voids

D. Pivovarov, J. Mergheim, K. Willner, P. Steinmann, in: PAMM, Wiley, 2021.

Influence of Kinematic Hardening on Clinch Joining of Dual-Phase Steel HCT590X Sheet Metal

J. Friedlein, J. Mergheim, P. Steinmann, in: The Minerals, Metals & Materials Series, Springer International Publishing, Cham, 2022.

Observations on additive plasticity in the logarithmic strain space at excessive strains

J. Friedlein, J. Mergheim, P. Steinmann, International Journal of Solids and Structures 239–240 (2022) 111416.

A Review on the Modeling of the Clinching Process Chain - Part III: Operational Phase

B. Schramm, S. Harzheim, D. Weiß, T.D. Joy, M. Hofmann, J. Mergheim, T. Wallmersperger, Journal of Advanced Joining Processes (2022).

A Review on the Modeling of the Clinching Process Chain - Part I: Design Phase

B. Schramm, S. Martin, C. Steinfelder, C.R. Bielak, A. Brosius, G. Meschut, T. Tröster, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes 6 (2022).

A Review on the Modeling of the Clinching Process Chain - Part II: Joining Process

B. Schramm, J. Friedlein, B. Gröger, C.R. Bielak, M. Bobbert, M. Gude, G. Meschut, T. Wallmersperger, J. Mergheim, Journal of Advanced Joining Processes (2022).

Numerical analysis of failure modeling in clinching process chain simulation

C.R. Bielak, M. Böhnke, J. Friedlein, M. Bobbert, J. Mergheim, P. Steinmann, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

A calibration method for failure modeling in clinching process simulations

M. Böhnke, C.R. Bielak, J. Friedlein, M. Bobbert, J. Mergheim, P. Steinmann, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Influence of plastic orthotropy on clinching of sheet metal

J. Friedlein, C.R. Bielak, M. Böhnke, M. Bobbert, J. Mergheim, P. Steinmann, G. Meschut, in: Materials Research Proceedings, Materials Research Forum LLC, 2023.

Efficient gradient enhancements for plasticity with ductile damage in the logarithmic strain space

J. Friedlein, J. Mergheim, P. Steinmann, European Journal of Mechanics - A/Solids 99 (2023).

Material Parameter Identification for a Stress-State-Dependent Ductile Damage and Failure Model Applied to Clinch Joining

J. Friedlein, M. Böhnke, M. Schlichter, M. Bobbert, G. Meschut, J. Mergheim, P. Steinmann, Journal of Manufacturing and Materials Processing 8 (2024).

Modelling of stress-state-dependent ductile damage with gradient-enhancement exemplified for clinch joining

J. Friedlein, J. Mergheim, P. Steinmann, Journal of the Mechanics and Physics of Solids 196 (2025).

Application of stress-state-dependent ductile damage and failure model to clinch joining for a wide range of tool and material combinations

J. Friedlein, S. Lüder, J. Kalich, H.C. Schmale, M. Böhnke, M.C. Schlichter, M. Bobbert, G. Meschut, P. Steinmann, J. Mergheim, Journal of Advanced Joining Processes 11 (2025).

Show all publications